3D modelling analysis for structures across the UK

Utilising the power of FEA (Finite Element Analysis) and detailing software to design and detail structures with extreme efficiency. See your ideas brought to life digitally with Richard Herrmann Associates Ltd – contact our office in Cambridgeshire today.

Using the latest in structural design software

By using advanced software including Finite Element Analysis (FEA) and RFEM, a software by Dlubal, within our models, we’re able to obtain the crucial detail that makes all the difference for your development. Going beyond the design, we can analyse how individual components behave under load, predicting the movement of materials, and identifying potential stress points quickly. The very latest versions of Revit and AutoCAD (both produced by Autodesk) are also used on projects where it is appropriate to do so.

For Richard Herrmann Associates Ltd it’s not just about avoiding structural failures. It’s about using modern technologies to optimise designs to promote cost-effectiveness for you without compromising on safety or robustness for the end user. We help our clients make informed decisions, backed by data and simulations, and you could be next to see the positive impact this can have on new developments and building enhancements.

3D modelling – the ultimate diagnostic tool

By putting innovative technologies to use during the planning and preparation phases, we’re able to look beyond the surface of the design to explore feasibility and suitability before construction begins. Structural analysis, deflection or distortion checks, and wind loading simulations are all part of this toolkit, and whilst each might sound a bit niche, they’re critical in understanding how external forces may impact the building or structure in the long run. The value of 3D analysis lies in its ability to factor in these variables, giving us a much clearer picture of how the structure will fair in the real world.

Taking a collaborative approach to structural design

We find that we can work with most file types that construction colleagues use, and this cross collaboration creates an efficient, connected design process for all parties involved. Whilst it might seem like a minor consideration, Richard Herrmann Associates Ltd knows that all specialists have something they bring to the table, and we facilitate the tools to do so. To stay ahead of the game, all software is fully maintained and updated regularly, allowing us to continue providing cutting-edge design capabilities.

37

Years Est.

6,500+

Clients

100+

Years' Experience

Highly regarded by our clients

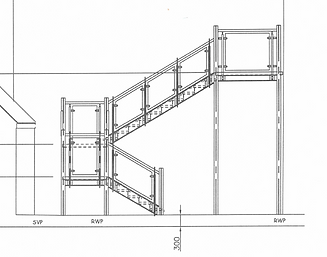

Case Study: External staircase for

King's School, Ely

We worked closely alongside the architect, Hollins Architects, Suffolk, to model, analyse and design the external staircases for a redevelopment project at the school.

We were appointed to assist with the creation of two new fire escape staircases to serve parts of the King's School at Ely. The architects, Hollins Architects, had designed an aesthetic, glass-balustraded, steel-framed staircase.

Our experience in providing the structural design of staircases that must be robust while achieving the architect's vision meant that we knew how to commence and what to prioritise while ensuring that the staircases met Building Regulations requirements as well as structural design codes.

We initially created an analysis model in RFEM (by Dlubal), which is an advanced structural finite element analysis software that is much better known on the continent than in the UK. It has been designed by structural engineers for structural engineers and is inherently more user-friendly and reliable than some other software.

The process commences with the creation of a series of 'sticks and pins' to replicate the staircase frame, but at this stage it is essential that the structural engineer understands how the frame will need to be fabricated, where joints in the structure will be, what type of joint will be suitable and how that joint should be 'modelled'.

The engineer would next connect the joints with 'members' and apply appropriate loads to the frame. Again, it's important at this stage that the engineer understands what the staircase will be used for and as well as what everyday loads will be applied, what extraordinary loads might also occur. An experienced engineer will take time to consider the 'what if' scenarios that might happen in the life of the staircase, from more likely events such as overcrowding from pupils watching a nearby sports field event, to the more remote possibility of a gas explosion from nearby storage of hazardous materials, or even vehicle impact from delivery vehicles.

Once the loads have been applied and the model analysed, we would be looking to check that the frame is acting in a manner that is expected, and that it is stable and able to resist the loads without excessive distortion or toppling/overturning. All structures deflect, distort or sag to varying degrees and again, this is something that an experienced engineer would limit to acceptable amounts. Although excessive movement of a structure would not necessarily cause it to collapse, it can lead to an unwanted perception of the structure being unsafe, and even make it un-useable, as was the case for the Thames Millenium Bridge at the start of the century!

Once we are happy that the deflection and sway values are acceptable we check that each individual member can safely resist the forces that might be applied to it, and we also design the connections between them. Connection design is another example of our input where we not only need to make sure that it is safe, but also that the connection is buildable and feasible for the fabricator.

Although the bulk of the design has been achieved by this stage, we still might need to ensure that the finer points are addressed, such as the support of any non-structural elements, handrailing, glass panels or similar.

We often also determine the nature of the foundations to the frame too. The foundation is a critical element, as it serves as the base upon which the entire structure rests. We need to assess soil conditions, load-bearing requirements, and any potential environmental impacts that could affect the stability of the foundation. This may involve conducting soil tests and having soil samples analysed to confirm their properties and strength.

By focusing on these finer details, we ensure that the design is not only visually appealing but also structurally sound and safe for use. It is essential that experience and professionalism is used to address any potential issues early on, which can save time and resources later in the project. Ultimately, the goal is to create a cohesive design that harmonizes all elements, resulting in a finished product that meets both aesthetic desires and practical needs.

If you are procuring, designing or fabricating structures and would like our assistance, please do get in touch.

CLIENT

Kings School, Ely

VALUE

£300k

LOCATION

Ely

ARCHITECT

Hollins Architects

Use 3D modelling to transform your project

Put your design to the test! Complete our online form to discuss the intricacies of your plans or call our team, based in Cambridgeshire, on 01480 455179 for general questions.